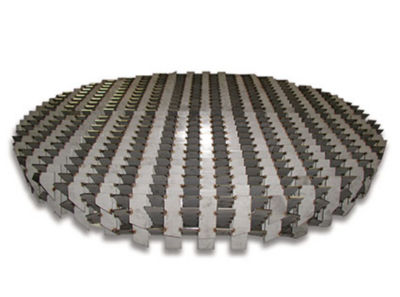

For demanding gas-solid fluidized bed systems, KFBE fluidized bed structured packing from Koch-Glitsch enhances gas-solid contact without restricting flow.

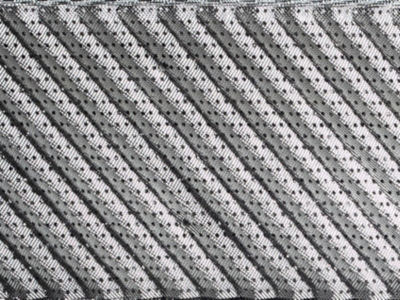

Designed for the demanding needs of gas-solid fluidized bed systems, KFBE structured packing enhances gas-solid contact without restricting flow or allowing solids stagnation. The rugged metal plates turn and break up the catalyst, promoting uniform fluidization and slow, uniform descent of catalyst through the stripper. As steam rises in small turbulent bubbles, hydrocarbon is efficiently stripped. The durable construction of this fluidized bed structured packing is not susceptible to mechanical failure, and the open design resists coking.

Although FCC catalyst stripping is the largest use of KFBE structured packing, the structured packing is also used in other services that need stripping/replacement of the fluidizing gas in a granular fluidized catalyst.

KFBE structured packing is supplied in layers that are contoured to fit any vessel configuration or packed column design. Each layer is comprised of packing blocks that fit through vessel manways. Designs account for out-of-round tolerance on vessels as well as for thermal expansion.

KFBE fluidized bed structured packing has these favorable features, compared to disc-and-donut or baffle/shed trays:

- Maximizes available capacity for catalyst and vapor flow

- Uses 95% of the vessel volume for process flow

- High process rates do not also mean local high, erosive velocities

- Maximizes uniform residence time

- Eliminates empty zones and stagnant zones of catalyst de-aeration

- Provides slow and uniform descent of catalyst through the stripper

- Improves stripping efficiency

- Provides maximum catalyst residence time with low catalyst velocity

- Improves contact through smaller bubble size

- Reduces channeling and bypassing

- Reduces erosion

- No pinch points of high velocity

- Low local velocities throughout entire bed

- Easy to install and maintain

- Weld-in supports and hold-down shell attachments are needed at top and bottom only

- Weld-in supports and hold-down shell attachments are permanent; the structured packing and its supports/hold-down grids are removable and replaceable

- Removable parts can be installed and removed quickly (for inspection or replacement)